February 16, 2026

February 16, 2026

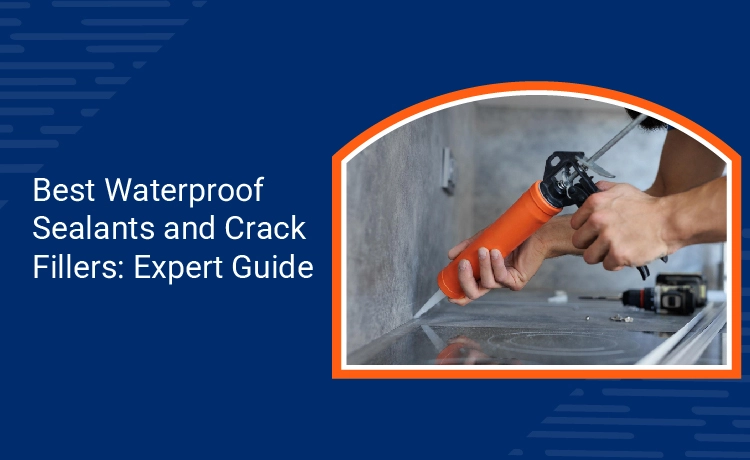

Cracks, gaps, and leaking joints are among the most common yet damaging problems in buildings and concrete structures. If left untreated or treated with the wrong product, they can lead to water seepage, dampness, mould growth, corrosion, and long-term structural deterioration. Choosing the right waterproof construction sealant or concrete crack filler is therefore critical for durability and protection. With many products available, understanding which weatherproof sealant, crack filler, or exterior joint sealant suits your application can be confusing.

This expert guide explains different sealant types, key selection criteria, and recommends high-performance solutions from MCON Rasayan, a trusted name in construction chemicals.

Waterproof and weatherproof sealants are specifically designed for areas exposed to rain, moisture, sunlight, and temperature variations. These sealants are commonly used in exterior walls, terrace joints, window and door frames, parapets, and expansion joints. A high-quality weatherproof sealant prevents water ingress while remaining flexible enough to handle thermal expansion and contraction.

Such sealants are ideal for sealing masonry joints, façade gaps, and external wall joints where long-term exposure to harsh weather conditions is unavoidable. Products with UV resistance and elastic recovery perform best in these applications.

Silicone crack fillers, polyurethane (PU), and polymer-based fillers are widely used to repair small to medium cracks in concrete, plaster, and masonry surfaces. These products offer excellent adhesion, flexibility, and resistance to moisture penetration.

Unlike rigid fillers, elastic crack fillers accommodate minor structural movement without reopening the crack. This makes them a preferred crack filler for walls and non-structural concrete cracks where waterproofing and flexibility are required.

For deeper or wider cracks, especially those affecting load-bearing elements, specialised concrete crack filler systems or polymer-modified repair mortars are required. These products restore structural integrity while preventing further crack propagation and seepage.

Proper surface preparation and product selection are essential to ensure long-lasting repair in such critical applications.

An exterior joint sealant is essential for joints between concrete, metal, glass, wood, and aluminium in façades, curtain walls, and window systems. These joints are constantly exposed to UV radiation, pollution, wind pressure, and moisture. High-performance sealants must resist ageing while maintaining elasticity and adhesion over time.

Interior sealants are used for minor cracks or gaps where weather resistance is less critical. These sealants often emphasise ease of application, smooth finish, and paintability rather than extreme durability.

Selecting the wrong sealant or a low-quality one can quickly lead to water seepage, recurring cracks, damp patches, mould growth, and costly repairs. In exterior applications, inadequate sealants often fail under UV exposure or temperature fluctuations.

A high-quality waterproof joint sealant or best sealant for concrete cracks does more than fill gaps, it adapts to structural movement, resists weathering, and protects against moisture ingress. The long-term benefits include reduced maintenance, extended lifespan of concrete and masonry, improved indoor comfort, and preserved aesthetics of the structure.

Always assess whether the surface is concrete, masonry, metal, wood, or mixed. Some sealants bond exceptionally well to concrete but poorly to metal or glass. Using a compatible exterior joint sealant ensures strong adhesion and long-term performance.

Hairline cracks require flexible fillers, while wider or moving joints demand elastomeric sealants. Structural cracks may require polymer-modified repair solutions. Choosing the correct crack filler for walls or concrete crack filler is essential to prevent failure.

Exterior applications demand sealants with excellent waterproofing, UV resistance, and tolerance to temperature variations. In damp or coastal areas, resistance to fungal growth and saline environments is equally important. A durable weatherproof sealant performs reliably in these harsh conditions.

Buildings naturally expand and contract due to thermal changes and loading conditions. A rigid filler may crack again, while an elastic sealant absorbs movement without damage. PU and polymer-based sealants are ideal where flexibility is critical.

A good sealant should resist ageing, water vapour transmission, microbial growth, and chemical exposure. Long-lasting performance reduces repair cycles and overall maintenance costs.

Products that are easy to apply, require minimal surface preparation, and allow repainting offer practical advantages on-site. Clean finishing and minimal shrinkage also improve results.

Using products from a reputable manufacturer ensures consistent quality, tested performance, and access to technical guidance. Companies with certified manufacturing setups and expert support offer greater reliability for critical applications.

MCON Rasayan is a trusted Indian manufacturer of advanced construction chemicals, offering high-performance solutions backed by technical expertise.

MCON Magic Seal PU is a premium PU-based waterproof construction sealant ideal for masonry, concrete walls, basements, external façade joints, windows, and door frames. It provides excellent adhesion, flexibility, and resistance to UV, ozone, dampness, and even light foot traffic, making it a reliable exterior joint sealant for demanding conditions.

For sealing small or micro cracks in concrete or masonry, MCON offers specialised concrete crack filler solutions from its sealant range, ensuring durable and moisture-resistant repairs.

MCON’s waterproofing system, used with its recommended primer, acts as both a waterproof coating and a protective barrier. It is especially effective for exterior walls exposed to heavy rainfall, humidity, or saline environments, preventing seepage and weather-related deterioration.

With certified manufacturing facilities, documented performance, and full technical support, MCON Rasayan ensures confidence, quality, and long-term durability.

Explore more products of MCON Rasayan through this guide: Which quick waterproofing solution to fill cracks is best?

Cracks and leaking joints should never be ignored, as they compromise both durability and safety. Choosing the right weatherproof sealant, silicone crack filler, or best sealant for concrete cracks depends on substrate, crack type, exposure, and movement requirements. High-quality products not only seal but also adapt to environmental stresses over time. With advanced solutions, supported by expert technical guidance, MCON Rasayan offers dependable protection for walls, façades, and concrete structures, ensuring long-lasting waterproofing, reduced maintenance, and preserved structural integrity. Contact us now!